Home > Products

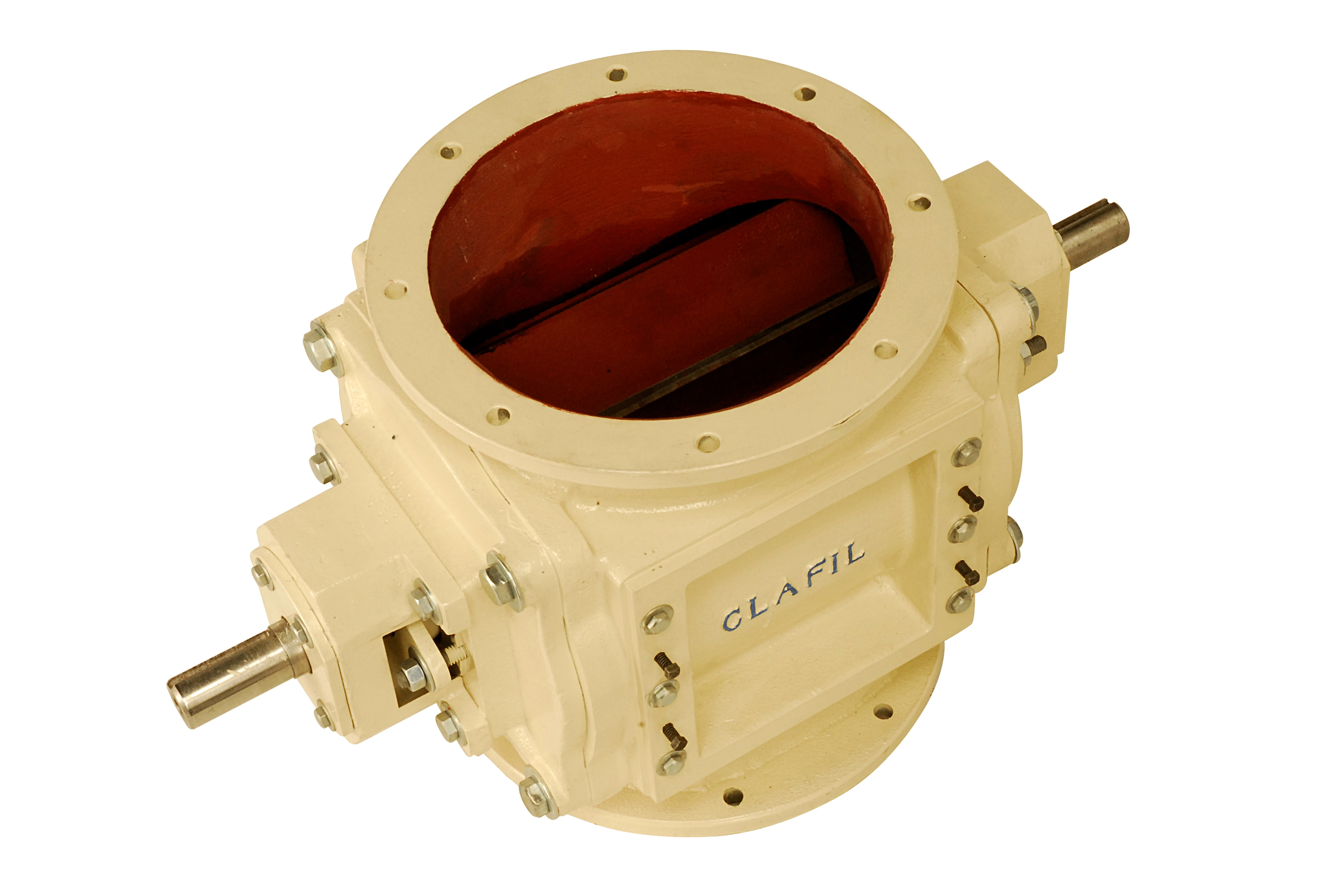

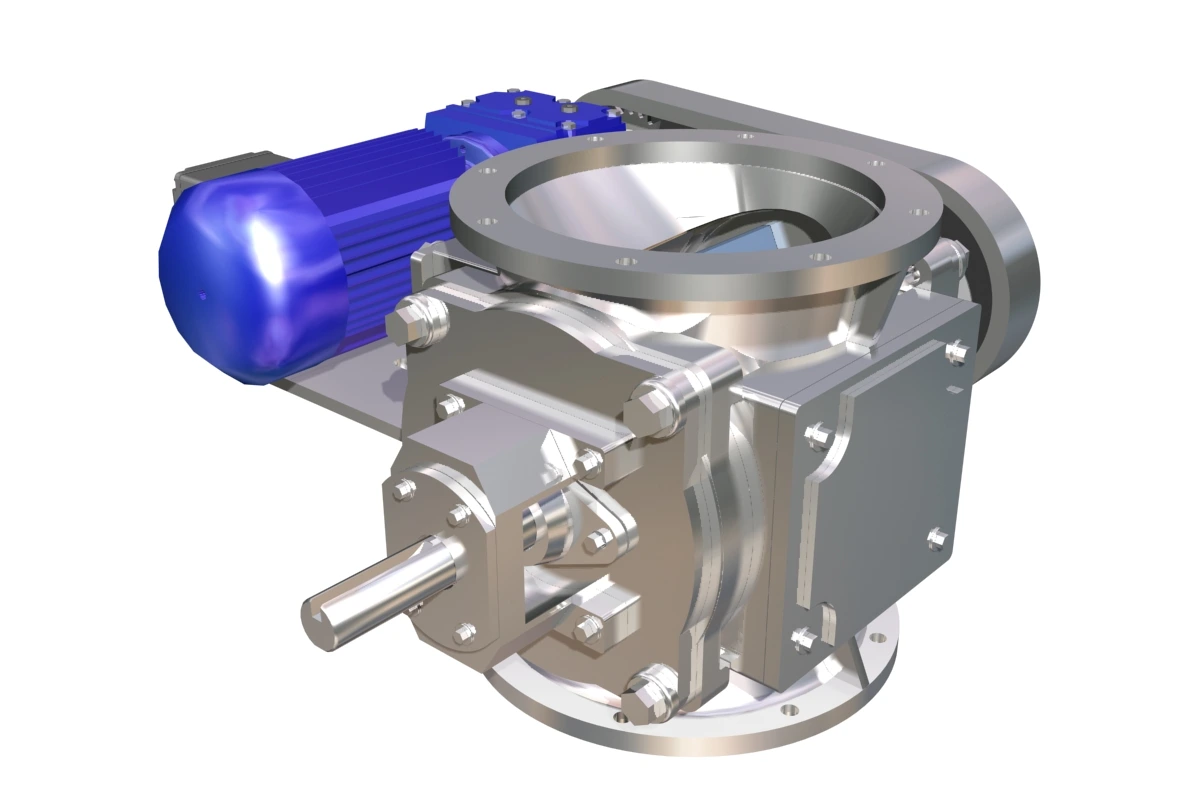

Rotary Valve

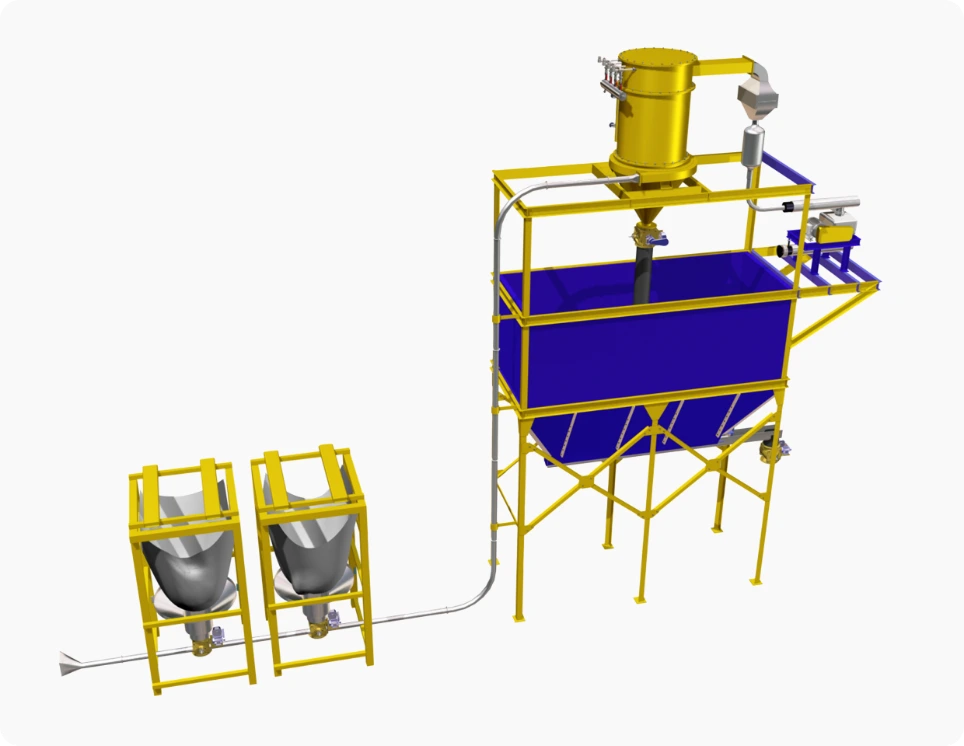

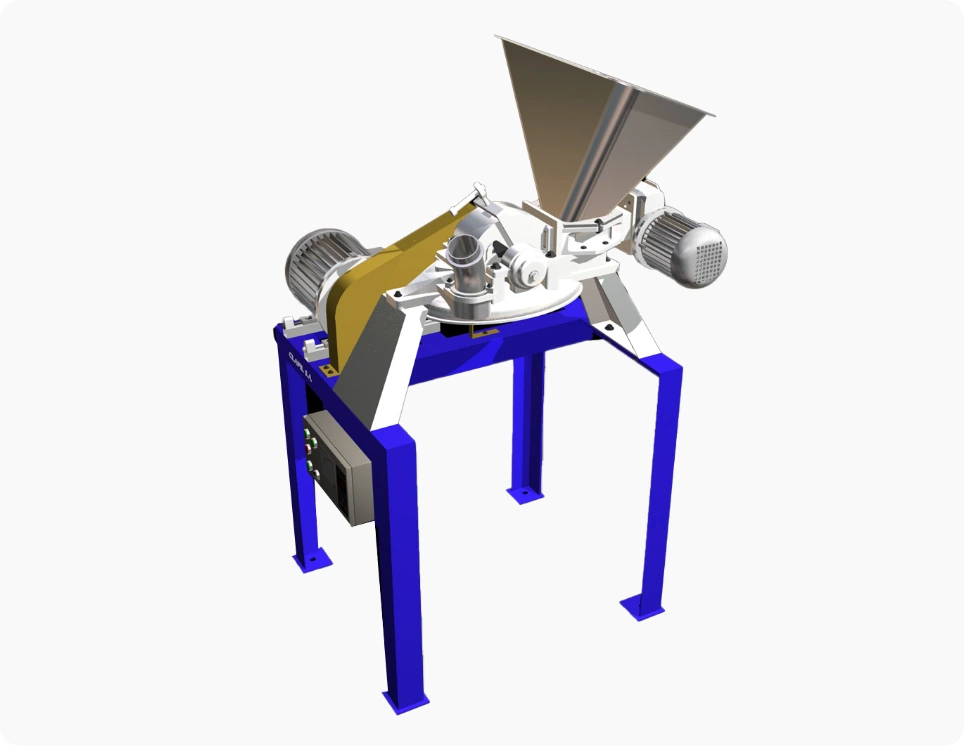

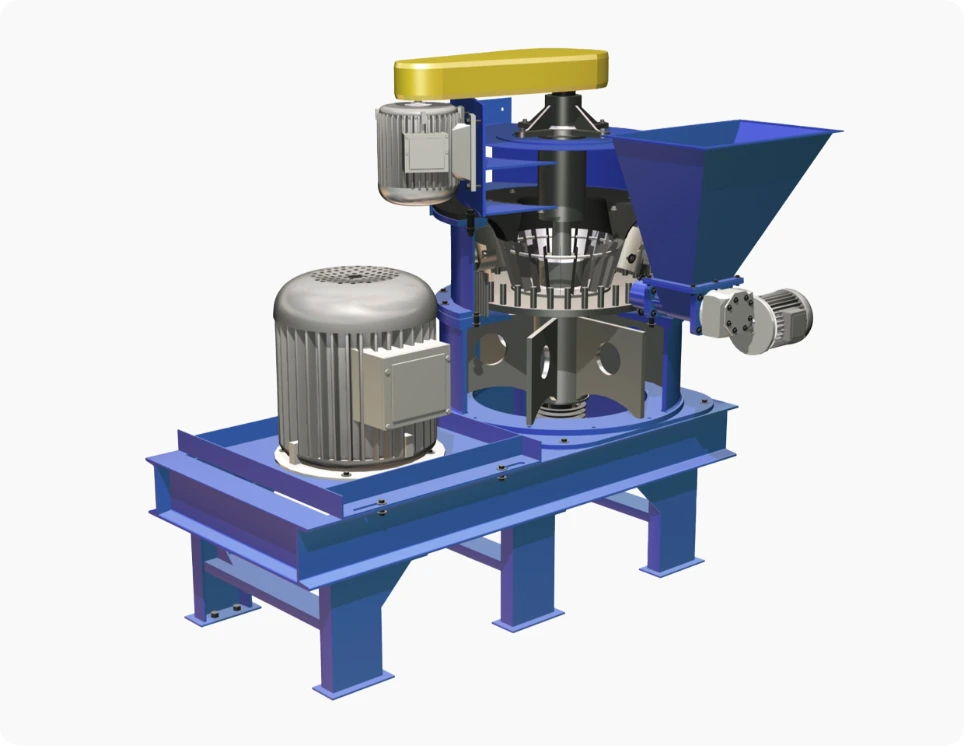

CLAFIL rotary valves or alveolar feeders are designed to regulate the flow of material between two compartments or a chamber and its discharge, maintaining an efficient pneumatic seal.

They are essential in handling dry or granular materials, especially in filtration and dust collection applications. These valves optimize the performance of cyclones and bag or cartridge collectors, ensuring efficient and continuous operation in various industrial processes.

CLAFIL rotary valves or alveolar feeders are designed to regulate the flow of material between two compartments or a chamber and its discharge, maintaining an efficient pneumatic seal.

They are essential in handling dry or granular materials, especially in filtration and dust collection applications. These valves optimize the performance of cyclones and bag or cartridge collectors, ensuring efficient and continuous operation in various industrial processes.

• Construction Materials: Cast iron, steel, stainless steel, or aluminum, designed for heavy-duty and continuous service.

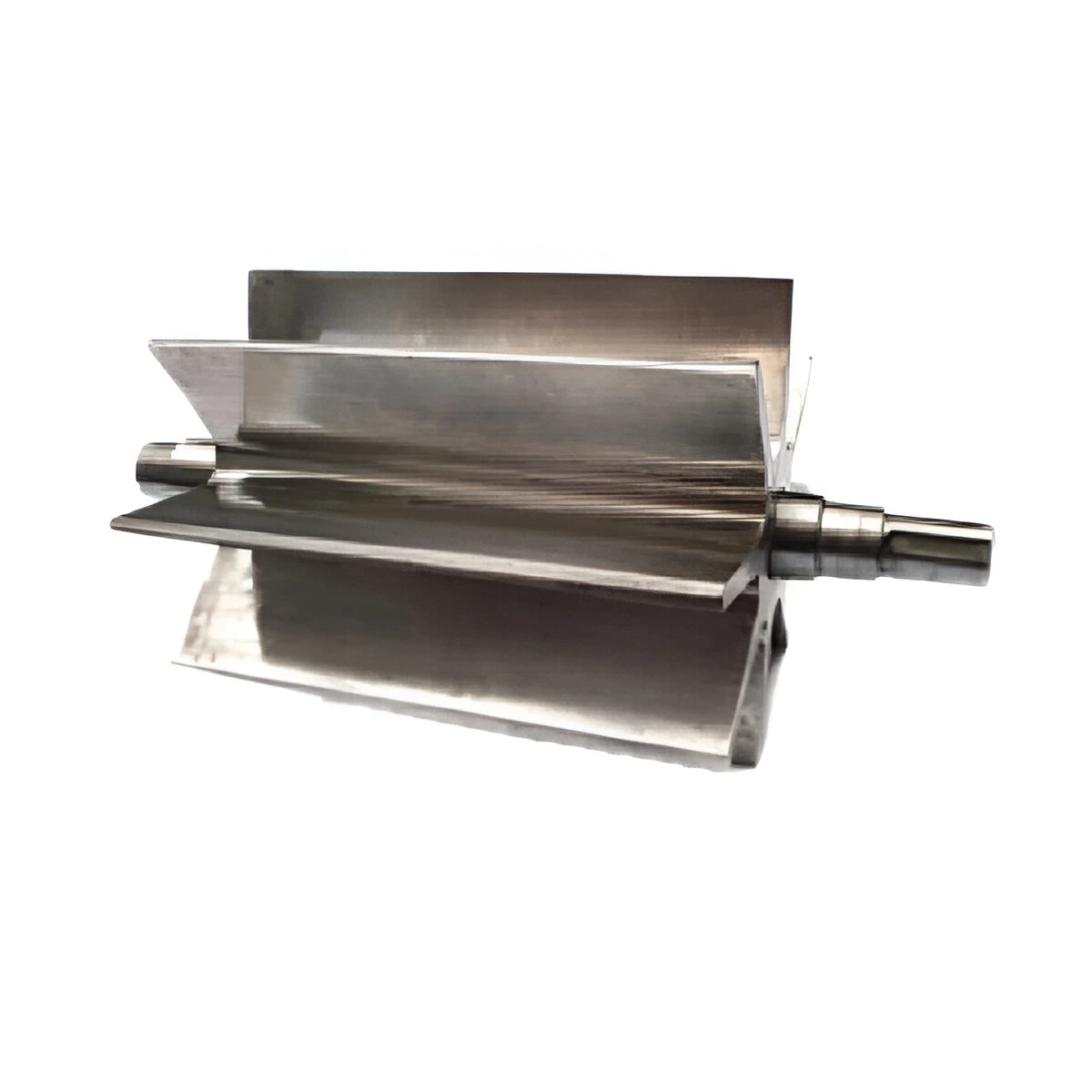

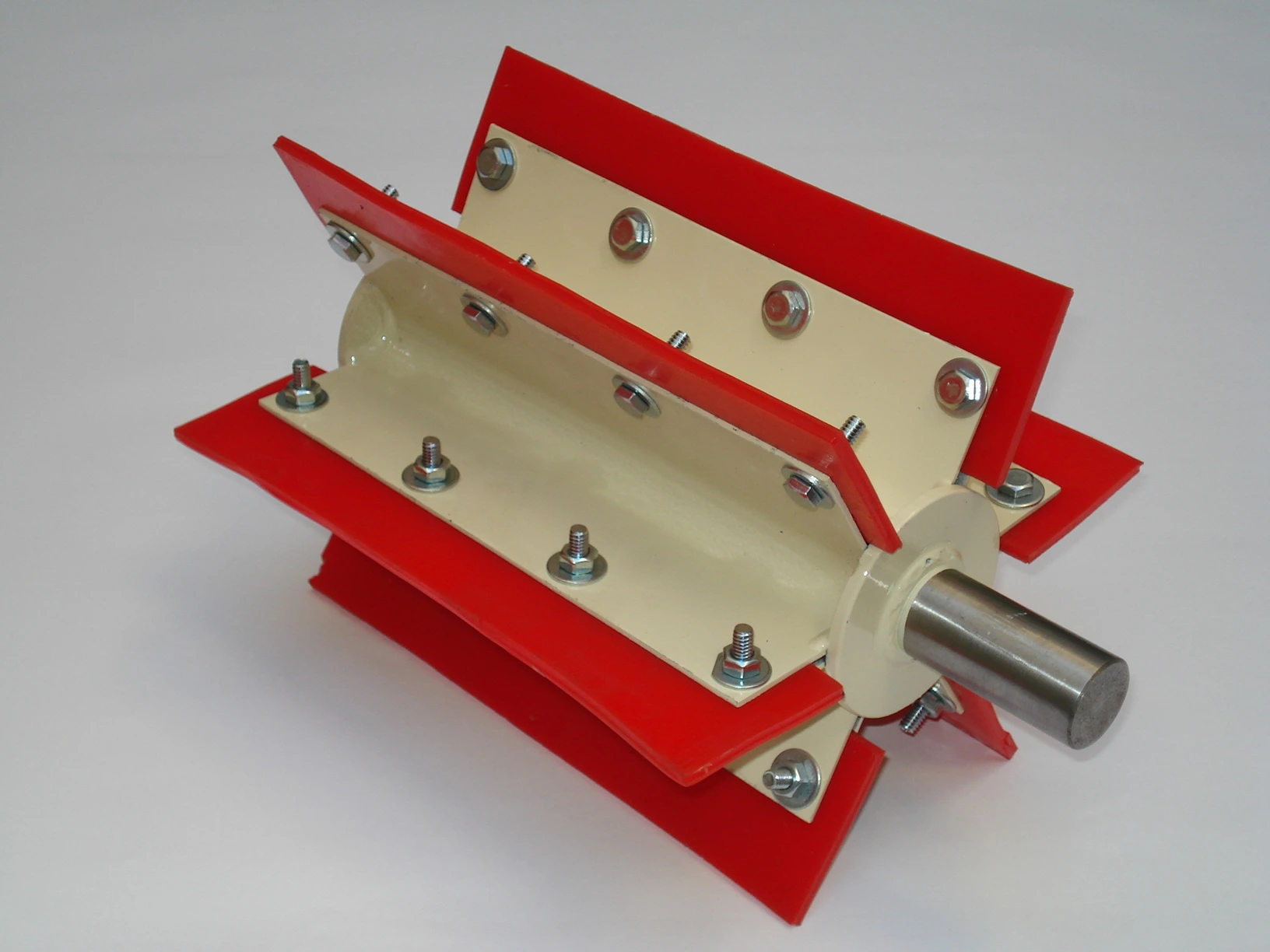

• Standard Rotors: Made of cast steel, cast iron, stainless steel, or aluminum with fixed or adjustable blades in various materials such as PVC, polyurethane, or Teflon. Reduced-capacity rotors are also available.

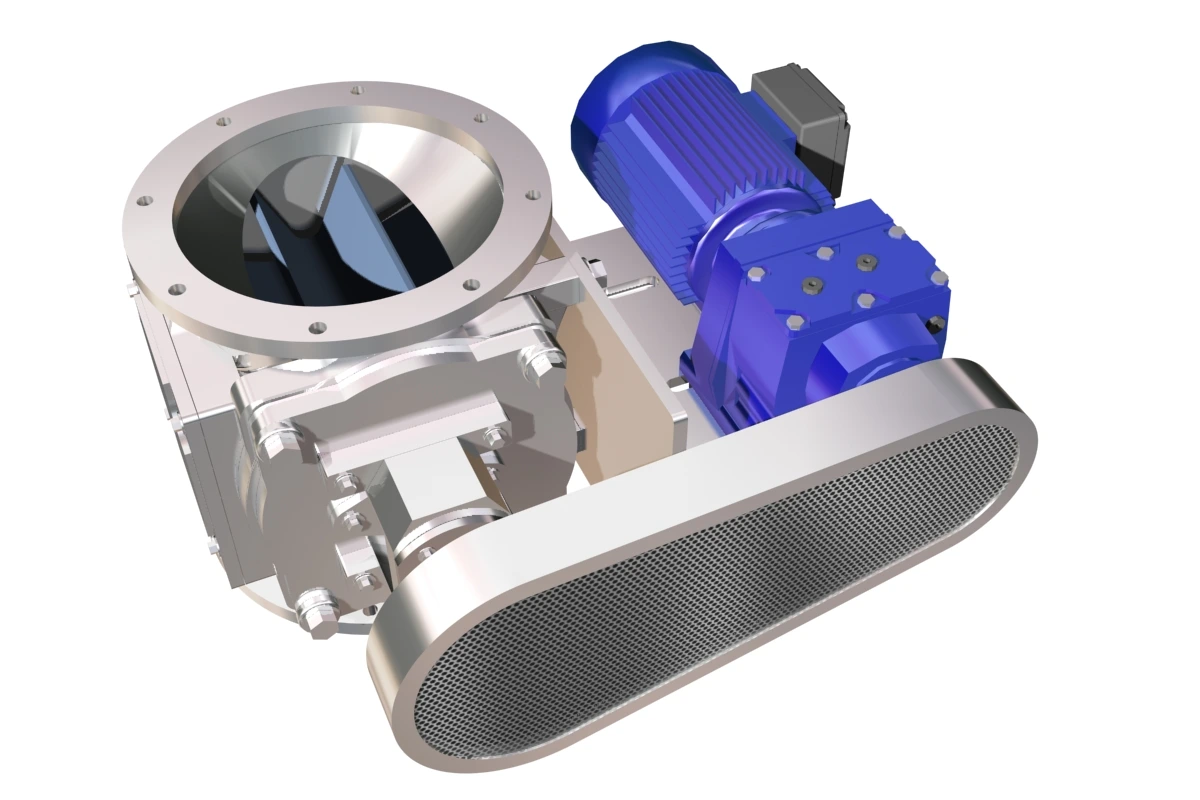

• Drive Options: Options for pinion and chain coupling - geared motor, or direct drive.

• Available Sizes: Models with rotors from 4” to 18”, with motors from 0.33 Hp to 10 Hp. They can operate at low differential pressure (up to 600 mmca) or high pressure (up to 3500 mmca).

• Bearings: Equipped with shielded bearings at both ends for greater durability and resistance.

• Inspection window in the body.

• Air purge.

• Rotation sensor.

• Directly coupled drive.

• Special anti-abrasion coatings.

• Double shaft ends.

• Separate packing gland from the body.